1. Overview and Application

TK-PCA polycarboxylate superplasticizer shows advantages in reducing water, maintaining high slump, retarding coagulation and resulting in early strength, and improving concrete durability, contains no chlorine and low alkali, and is non-toxic, pollution-free and environmentally friendly. Now it is widely used in high strength, high performance and durable concrete, as well as all kinds of ordinary concrete projects with internationally advanced indicators. Product indicators meet the requirements of GB8076-2008, JG/T223-2007, GB/T8077-2012, TB/T3275-2011 and so on. TK-PCA polycarboxylate superplasticizer has passed the CRCC certification for railway engineering.

2. Model and Usage

1. TK-PCA1 standard type: usual dosage of 0.8-1.5%; applicable to high-performance, high-strength, precast concrete projects, and concrete pumping at room temperature.

2. TK-PCA2 retarding type: usual dosage of 1.0-2.0%; retarding time can be adjusted from 3 to 40 hours according to the construction requirements through tests; applicable to large volume, underwater, self-compacting and large flow, high head and ultra-long-distance pumping of high-performance and high-strength concrete and general concrete projects at high temperature in summer.

3. TK-PCA3 early strength type: usual dosage of 1.5-2.5%; applied to improve the early strength of concrete projects requiring high performance, high strength, super-high strength and steam-cured products at low temperature.

3. Advantages

1. High water reducing ratio, high performance in maintaining slump.

2. Containing no chlorine and low alkali, being non-toxic and harmless.

3. This product can significantly reduce the amount of cementing materials to effectively reduce the project cost.

4. It can be adjusted to be a variety of admixtures based on construction site requirements.

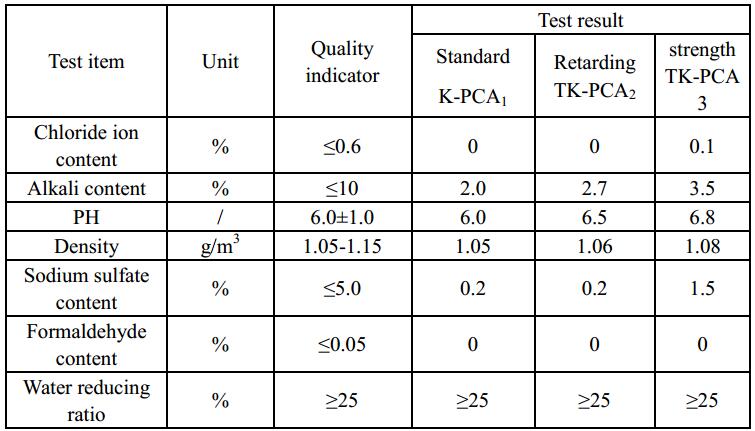

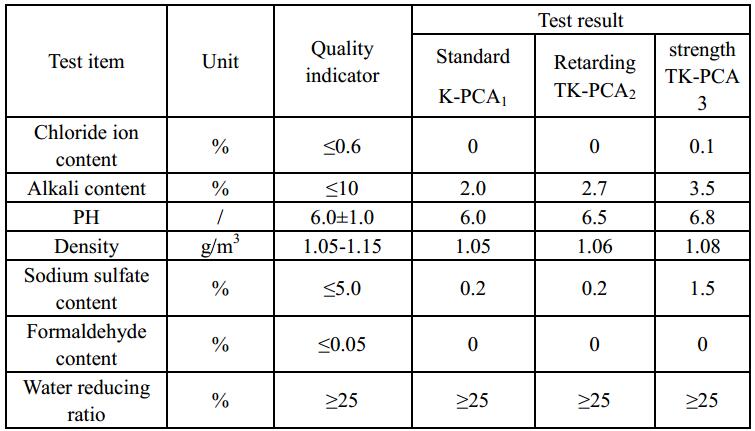

4. Main Performance Indicators

1. Homogeneity

Test reference standards: GB8077-2012, Enterprise standard Q/56446784-5.5-2013