1. Overview and Application

1. Overview and Application

Pipeline grouting agent (material) has micro-expansion but has no shrinkage; the compensation mechanism is that the grouting agent and cement hydration products react to form ettringite crystals, without chlorine ions and other harmful substances; with very low water cement ratio, it can get high liquidity and it is easy to use, pour; higher strength can be achieved soon. Its technical performance indicators are in line with TB/T3192-2008 Technical Specification for Pipeline Grouting on Post-tentioned Pre-stressed Concrete Railway Girder and JTG/T F50-2011 Highway Bridge Construction Specifications.

2 . Product Model and Usage

1. TK-GY1 pipeline grouting agent, based on total cementing materials (8% to 12% if mixed internally, high dosage type: 5.0-10%)

2. TK-GY2 pipeline grouting agent can be directly mixed with water and stirred.

3. The water-cement ratio: less than 0.33 (in line with TB/T3192-2008), 0.26 ~ 0.28 (in line with JTG/T F50-2011)

4. Application: Widely used in filling grouting materials for post-tensioned beams prestressed pipe, to prevent corrosion of prestressed steel and ensure effective stress transfer between prestressed constraint and prestressed concrete structures, so that the grout within the pore is compacted. TK-GY concrete pipeline grouting agent (material) used in various engineering can achieve high strength, high crack resistance, impermeability, no shrinkage, high adhesion, corrosion and rust resistance.

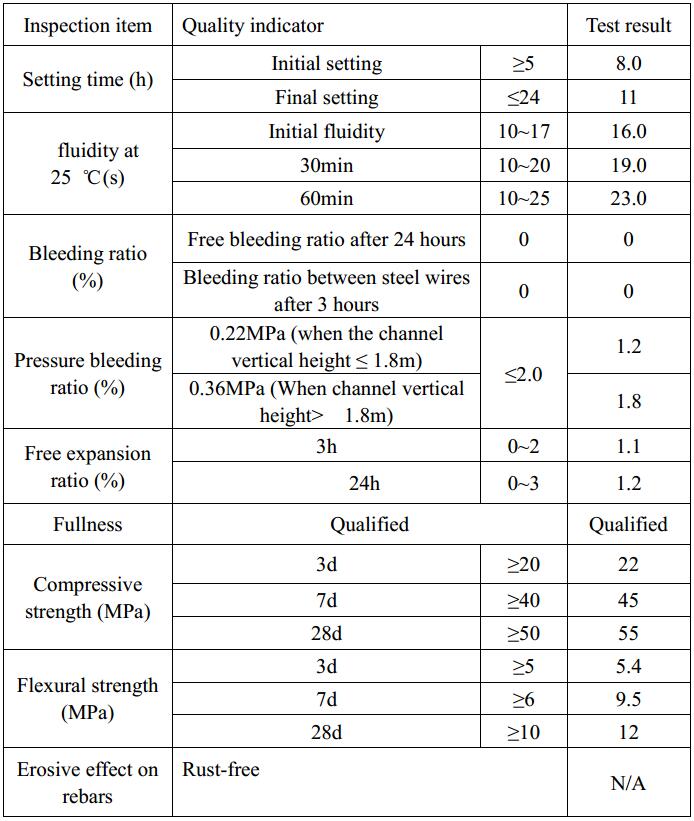

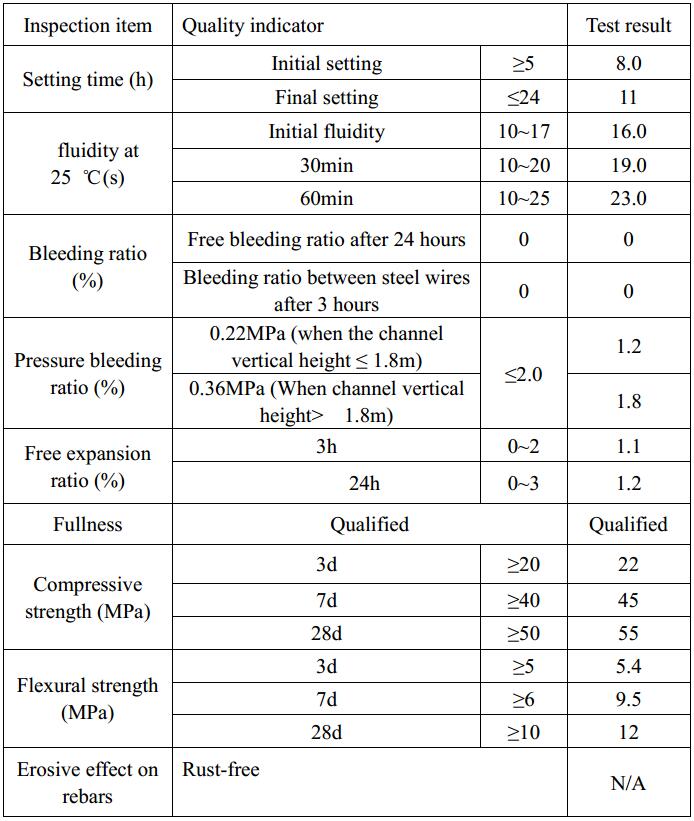

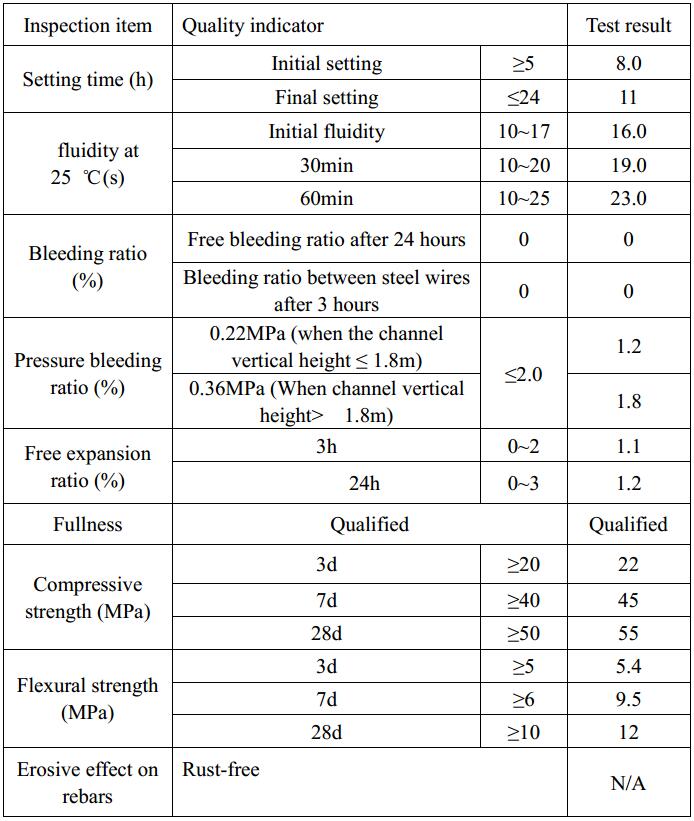

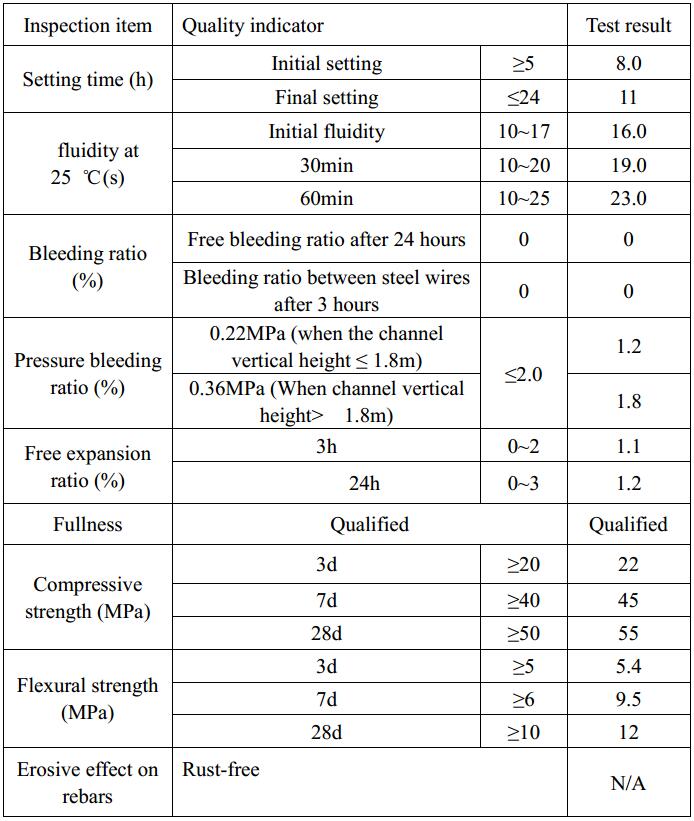

3. Main Performance Indicators

Test basis: JTG/T F50-2011 (Highway Bridge Construction Specifications)

Test basis: TB/T3192-2008 (Technical Specification for Pipeline Grouting on Post-tentioned Pre-stressed Concrete Railway Girder)

3. Packaging, Transportation and Storage

3. Packaging, Transportation and Storage

It is packaged in sealed plastic-lined poly-woven bags. Each grouting agent (material) has a net weight of 25kg ± 0.2kg. Products shall be stored at room temperature in a cool and dry place, protected from breakage, high temperature and any damage to the package; shelf life of grouting material is 90 days; shelf life of grouting agent is 180 days.