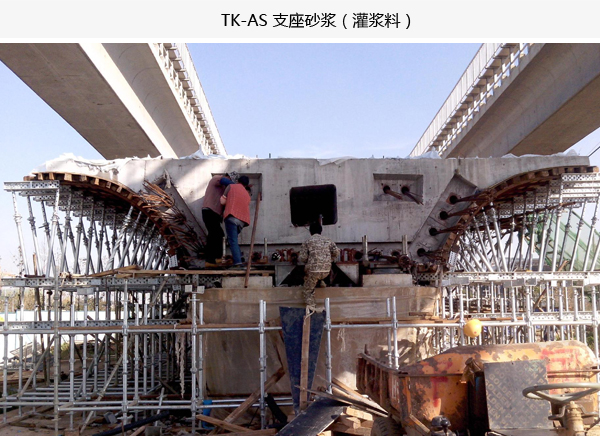

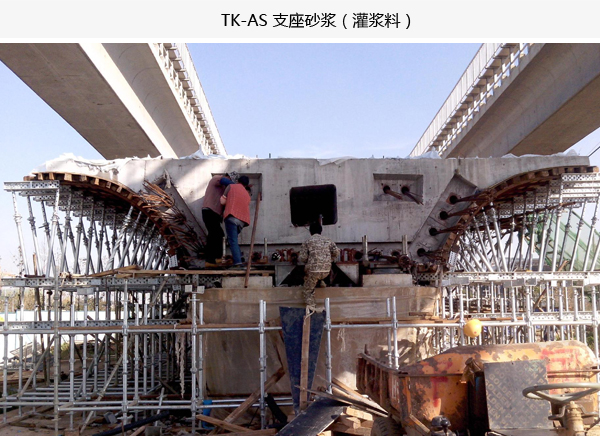

1. Overview and Application

1. Overview and Application

TK-AS has physical and chemical properties such as micro-expansion, ultra-early strength, high strength, no shrinkage or cracking, high resistance to oil/water seepage, corrosion resistance, freeze-thaw resistance and rust resistance. It renders fresh mortar of fluidity, scalability, good workability, smooth molding paste, high compactness and good homogeneity. It can be used at negative temperature and low temperature. It can exhibit excellent early strength properties, high strength, without shrinkage. The quality of TK-AS has been tested by the product testing center of the Ministry of Railways, the state (provincial) Building Materials Quality Supervision, Inspection and Testing Center. Its technical performance indicators are in line with scientific and technological requirements of 101 [2005] Interim technical conditions of railway bridge rubber bearing basin, GB/T50448-2008.

2. Product Model and Usage

TK-AS1 base mortar: The product is mainly used in bridge base gravity grouting, channels mortar for post-tensioned high-strength wire tendon and prestressed concrete members. The mortar is intended to be used for railway construction. It can brings non-shrinkage, micro-expansion, ultra-early-strength, ultra strength without being vibrated in pouring mortars, with self-leveling, self-compacting.

TK-AS2 grouting material: mainly used for grouting equipment foundation anchor bolts, base secondary grouting, grouting pad and repairing bolt joint, anchor bolts, concrete structures, connections between steel and concrete structures, member pore connection, repairing and strengthening roads and bridges, concrete (mortar) defects, anchor, anchor bolts and spikes.

1. The product is simple to use; the ratio of water to mortar is water: mortar = 0.13 to 0.16:1, so the liquidity can meet the construction requirements; fully mix it for 2 to 4 minutes (with a forced mixer) until it is uniform before grouting.

2. The base to be grouted should be fully clean, with no dust, no oil stains and maintain adequate moisture and no water.

3. Pour the mixed grouting material into the channel continuously to fully fill it.

4. Curing conditions: When the surface of the grouting material is whitish (after the initial setting, before the final setting), immediately cover and cure with water, and keep the surface wet sufficiently, especially type Ⅰbase mortar; in winter, when the temperature falls below 5 ℃ , use thermal insulation curing to prevent damage due to great temperature difference for inner heat and outer freeze; curing shall last no less than 3 days.

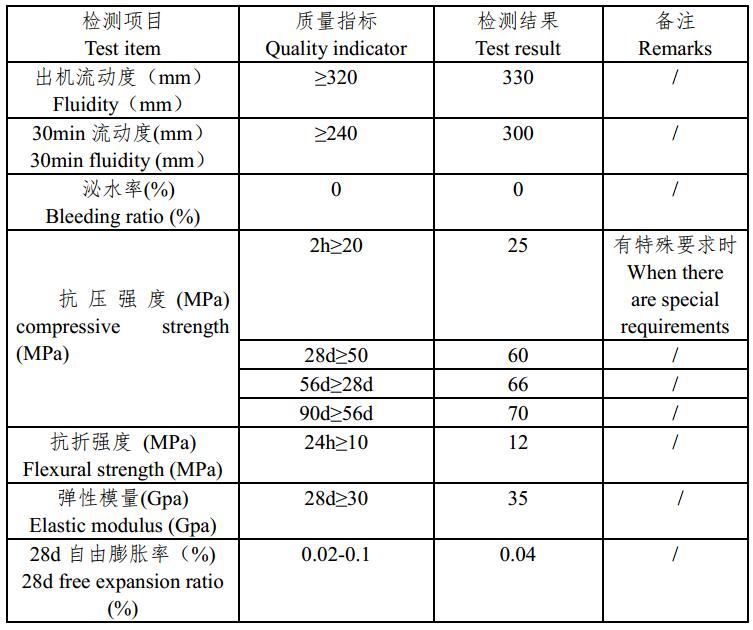

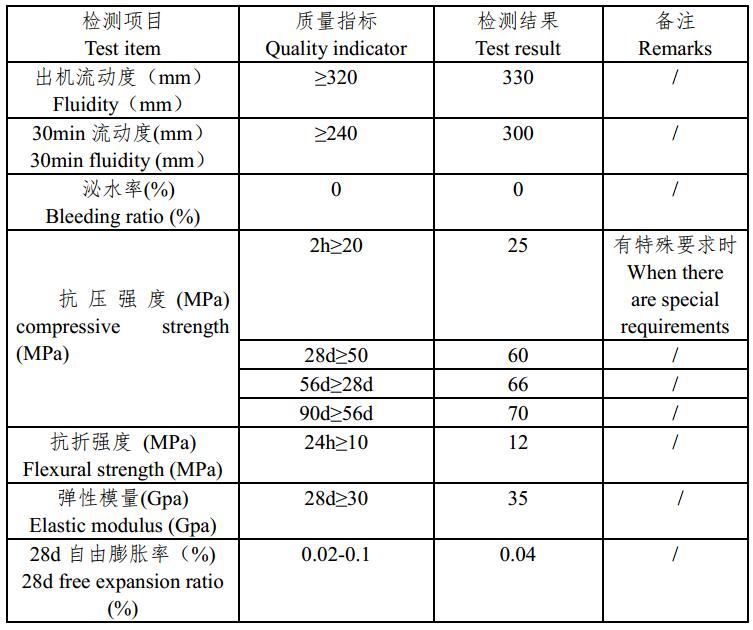

3. Performance Indicators

TK-AS

1 base mortar technical performance indicators

TK-AS1 reference standards: Technology Fund [2005] No. 101 Interim technical conditions of railway bridge basin-type rubber base

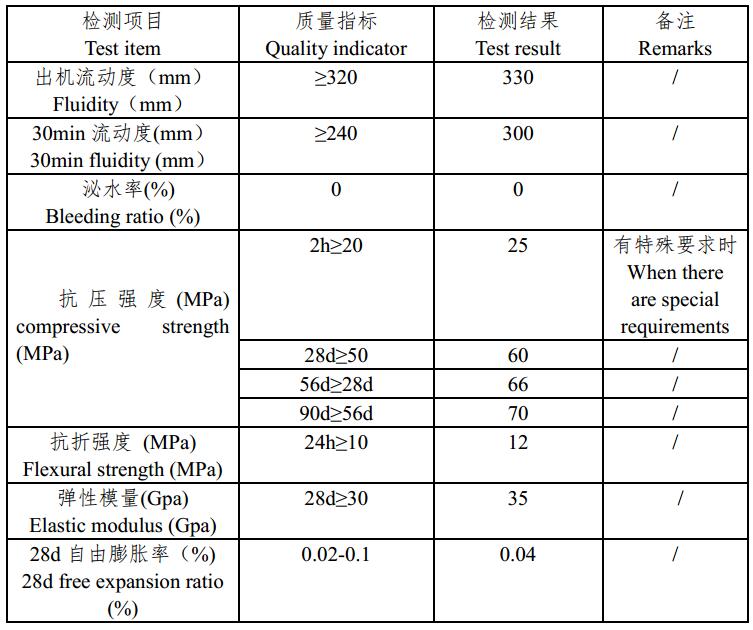

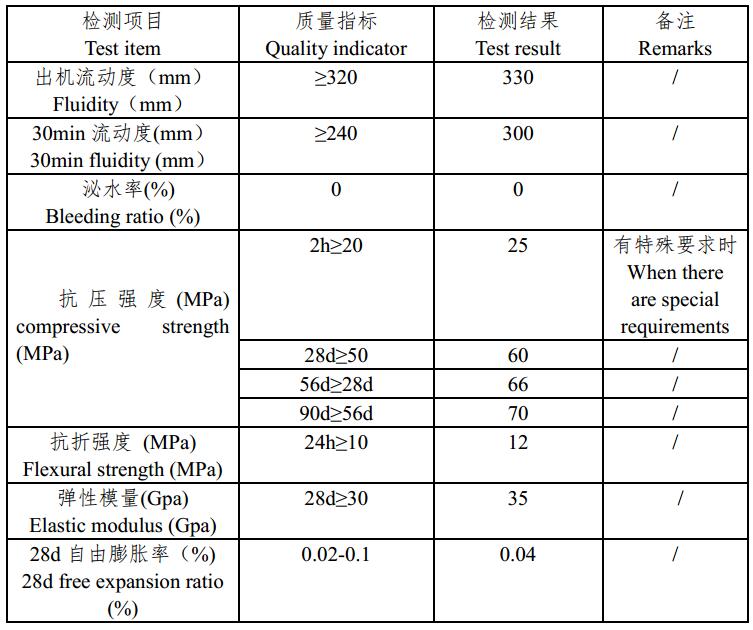

Reference standard for technical performance indicators of TK-AS

2 grouting material:GB/T50448-2008

4. Packaging, Transportation and Storage

4. Packaging, Transportation and Storage

This product is solid, packaged in plastic-lined poly-woven bags (or paper bag), weighing 25kg or 50kg. Its shelf life is 90 days if it is sealed and stored at room temperature in a dry and cool warehouse and protected from water, moisture and damage.