1. Overview and Application

TK-AP anti-corrosion sealing agent is mainly used in high performance concrete, anti-corrosion concrete, air-tight concrete, concrete resistant to diffusion of chloride ion, anti-cracking concrete placed in railway, tunnel, highways, coast, power stations, civil buildings, chemical construction, oil construction, national defense construction, and aviation construction to resists cracking, seepage, freeze, carbonization, oil seepage, leakage of toxic gas, as well as repair plugging requirements, sprayed concrete and mortar, durable concrete mortar projects. The indicators meet technical requirements of JC/T1011-2006 and JC/T313-2009 .

2. Product Model and Usage

1. TK-AP1 standard type: dosage 6.0-8.0% (high concentration type: dosage 3.0-6.0%), applicable to non-pumping anti-corrosion air-tight ordinary concrete or sprayed airtight ordinary corrosion-resistant concrete .

2. TK-AP2 compound type: dosage (internally mixed) 8.0 to 12%, mainly used for pumping airtight, corrosion-resistant concrete; it has advantages in blocking and adsorbing corrosive media, reducing crack, compacting the concrete for better impermeability, plasticizing, reducing water, entraining air, pumping, retarding, enhancing, resisting corrosion, causing air tightness, resist freeze, carbonation, abrasion, inhibiting alkali aggregate reaction, resisting rust and protecting rebars.

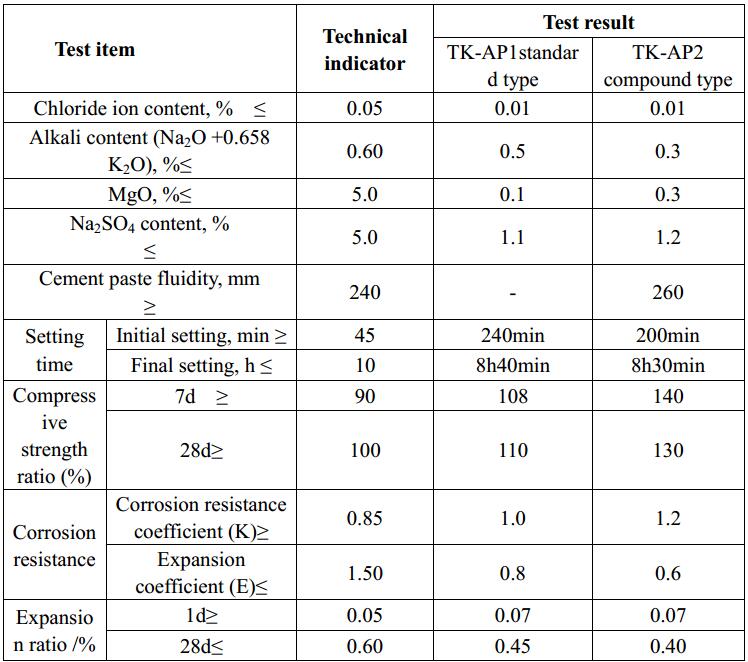

3. Main Performance Indicators

Based on GB/T8077-2012, JC/T1011-2006, GB8076-2008, JC/T313-2009.